PakAlumni Worldwide: The Global Social Network

Some of Prime Minister Narendra Modi's supporters claim that his "Make in India" campaign has brought India to the verge of becoming a manufacturing behemoth 69 years after the nation's independence. Others claim India is already a manufacturing powerhouse. Let's examine these claims based on data.

Manufacturing Ranking:

While India now ranks 6th in the world in terms of total manufacturing output, it still sits at a very low 142nd position terms of manufacturing value added per capita, according to the United Nations Industrial Development Organization's Industrial Development Report 2016. Pakistan's manufacturing value added is ranked 146th by the same report.

Manufacturing Output:

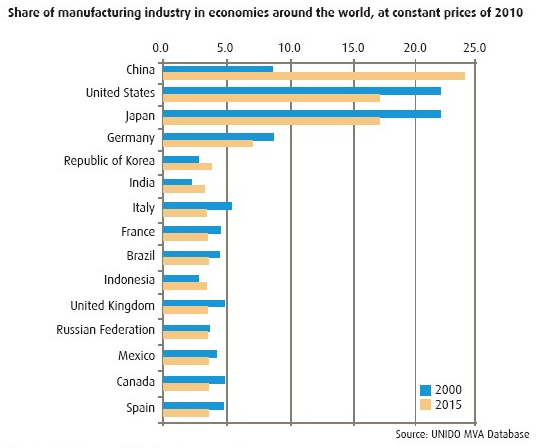

India's 3% share of the world's total manufacturing output puts it at a distant sixth position behind China's 24%, United States' 17%, Japan's 16%, Germany's 7% and South Korea's 4%.

The UNIDO data shows that India's manufacturing value added (MVA) per capita at constant 2005 prices increased from US$155.73 in 2005 to $168.42 in 2014. However, as percentage of GDP at constant 2005 prices in US$, India's MVA decreased from 15.10% in 2005 to 13.85% in 2014

UNIDO reports that Pakistan manufacturing value added (MVA) per capita at constant 2005 prices increased from US$135.03 in 2005 to $143.84 in 2014. Its MVA as percentage of GDP at constant 2005 prices in US$ decreased from 18.05% in 2005 to 17.41% in 2014.

India's manufacturing output declined 0.7% in April-June 2016-17 |

Make in India:

Prime Minister Narendra Modi has recognized how far behind India is in the manufacturing sector. His government's highly publicized "Make in India" is designed to Change that.

What does India, or for that matter any other developing country, need to boost its manufacturing output? Most experts agree on two essential pre-requisites for industrial development:

1. Energy and Infrastructure

2. Skilled Manpower

China's rapid industrialization over the last few decades has shown that the focus must be on the above two to achieve desired results. Has India learned from the Chinese experience? Let's examine this question.

Energy and Infrastructure Development:

"Infrastructure is the biggest hurdle to the ambitious Make in India program of the government," Standard and Poor Global Ratings Credit Analyst Abhishek Dangra told reporters on a conference call, according to India's Economic Times publication.

"The government is scaling up spending, but its heavy debt burden could derail its ambitions to improve public infrastructure," the Standard and Poor report said.

India suffers from huge energy deficit. Over 300 million of India’s 1.25 billion people live without electricity. Another 250 million get only spotty power from India’s aging grid, with availability limited to three or four hours a day, according to an MIT Energy Report. The lack of electricity affects rural and urban areas alike, limiting efforts to advance both living standards and the country’s manufacturing sector.

Skilled Manpower:

“India doesn’t have a labor shortage—it has a skilled labor shortage,” said Tom Captain, global aerospace and defense industry leader at Deloitte Touche Tohmatsu, according to a Wall Street Journal report.

The WSJ report said that over 80% of engineers in India are “unemployable,” according to Aspiring Minds, an Indian employability assessment firm that did a a study of 150,000 engineering students at 650 engineering colleges in the country.

NPR's Julie McCarthy reported recently that ten million Indians enter the workforce every year. But according to the Labour Bureau, eight labor-intensive sectors, including automobiles, created only 135,000 jobs last year, the lowest in seven years.

Impact on Agriculture:

Prime Minister Modi's focus on manufacturing is talking away resources and attention from India's farmers who are killing themselves at a rate of one every 30 minutes.

Majority of Indian farmers depend on rain to grow crops, making them highly vulnerable to changes in weather patterns. As a comparison, the percentage of irrigated agricultural land in Pakistan is twice that India.

More than half of India's labor force is engaged in agriculture. Value added per capita is among the lowest in the world. Pakistan's agriculture value added per capita is about twice India's. This is the main cause of high levels of poverty across India.

Chinese Experience:

China has shown that it is possible to make huge strides in manufacturing while at the same time achieve high productivity levels in agriculture.

On the manufacturing front, China has taken care of the basics like energy, infrastructure and skilled manpower development to achieve phenomenal growth.

As part of the China-Pakistan Economic Corridor (CPEC) development, Pakistanis are learning from the Chinese to replicate success in manufacturing.

The first phases of CPEC are focused on building power plants, gas pipelines, rail lines, roads and ports at a cost of $46 billion. At the same time, China and Pakistan are also focussing on skills training via vocational schools and Pakistan-China Education Corridor. These projects will lay the foundation necessary to ramp up manufacturing in Pakistan.

Summary:

Both India and Pakistan want to emulate the success of China in the manufacturing sector. The Chinese experience has shown that development of energy, infrastructure and skilled labor are essential to achieve their manufacturing ambitions. The South Asians must move beyond hype to do the hard work necessary for it. Pakistan is working with China via CPEC to make progress toward becoming a manufacturing powerhouse.

Related Links:

Auto Industry in India and Pakistan

UN Industrial Development Report 2016

China-Pakistan Economic Corridor

Riaz Haq

Exclusive: Russia's Sberbank says India business booming despite Western sanctions | Reuters

https://www.reuters.com/business/finance/russias-sberbank-says-indi...

MOSCOW, Sept 3 (Reuters) - Russia's trade with India is booming and bilateral payments are proceeding smoothly without the glitches that have been hampering trade with other countries, Anatoly Popov, deputy CEO of Russia's largest lender, Sberbank, told Reuters.

Sberbank handles payments for up to 70% of all Russian exports to India. Russia's trade with India nearly doubled to $65 billion in 2023, with the country becoming a major importer of Russian oil after Western sanctions imposed in 2022 over a conflict in Ukraine.

----

Sberbank is under Western sanctions and therefore cannot make transactions in U.S. dollars and euros or use the SWIFT system for international transfers. However, Popov said the bank has not experienced any problems in India.

"Sberbank is a full participant in all Indian payment and interbank systems. There are no restrictions on its operations," Popov said. India has not joined any anti-Russian sanctions and maintains friendly relations with Russia, a fellow member of the BRICS group of emerging economies.

----------

"The problem has been solved, there is no rupee surplus any longer," Popov said, emphasising that to achieve balanced trade, India still needs to increase its exports to Russia 10-fold. An Indian source told Reuters on Aug. 14 that the rupees surplus has dropped to a "few million dollars".

He said that India, the world's fifth largest economy, had almost everything Russian importers were looking for.

"India is a self-sufficient, vast economy capable of meeting its own needs. Therefore, any goods that Russia previously imported can be purchased in India," Popov said.

Sberbank is also developing its offering of hedging instruments, which already includes forwards and options, as well as other products such as rupee-denominated loans for Russian companies at rates significantly lower than in Russia.

He thanked Indian regulators for the opportunity to operate through rupee-denominated "vostro" accounts, which domestic banks can hold on behalf of foreign banks in India, facilitating their operations.

Popov said that the current mechanism of converting roubles and rupees was functioning well and did not require any third-party currencies for settlement. However, he emphasized that stock exchange trade in rupees would increase transparency.

----------------------------------

Indian reliance on Chinese imports is challenge for U.S. trade strategy - The Washington Post

https://www.washingtonpost.com/world/2024/09/02/india-china-manufac...

NEW DELHI — American businesses looking to reduce their reliance on China have increasingly been eyeing India in the past few years as a new manufacturing hub — and as a hedge against potential disruptions in Chinese supply chains caused by rising geopolitical tensions or another pandemic.

But as India has amped up its production of goods like smartphones, solar panels and medicine, the Indian economy itself has become even more dependent on Chinese imports, in particular for the components that go into these products, according to trade figures and economic analysts.

This dynamic serves as a reality check for U.S. policymakers, who have been urgently promoting efforts to diversify supply chains away from Chinese factories and “de-risk” the commercial relationship with China.

“Unless China stops being the third party from where components come in and we just assemble, that de-risking is not going to happen for any country coming in and producing in India,” said Sriparna Pathak, an associate professor at Jindal University focusing on India-China relations.

Sep 2, 2024

Riaz Haq

Indian reliance on Chinese imports is challenge for U.S. trade strategy - The Washington Post

https://www.washingtonpost.com/world/2024/09/02/india-china-manufac...

NEW DELHI — American businesses looking to reduce their reliance on China have increasingly been eyeing India in the past few years as a new manufacturing hub — and as a hedge against potential disruptions in Chinese supply chains caused by rising geopolitical tensions or another pandemic.

But as India has amped up its production of goods like smartphones, solar panels and medicine, the Indian economy itself has become even more dependent on Chinese imports, in particular for the components that go into these products, according to trade figures and economic analysts.

This dynamic serves as a reality check for U.S. policymakers, who have been urgently promoting efforts to diversify supply chains away from Chinese factories and “de-risk” the commercial relationship with China.

“Unless China stops being the third party from where components come in and we just assemble, that de-risking is not going to happen for any country coming in and producing in India,” said Sriparna Pathak, an associate professor at Jindal University focusing on India-China relations.

—————

To support the production of Indian textiles and garments, another important export industry, India has been ramping up imports of yarn and fabric from China. Even the automobile industry — considered a success story for both domestic and export sales — has been increasing its imports of vehicle parts and accessories from China.

As with electronics, India has made significant strides in producing solar panels but now relies even more on the Chinese solar cells that go in them.

After the United States restricted imports of Chinese solar panel material because of concerns about human rights and labor abuses, Indian exports of solar panels to the American market spiked in 2022, increasing in value by almost 150 percent, according to U.S. government trade figures. The next year saw an even sharper increase.

During that time, however, India sourced between half and all of its solar panel components — such as modules, cells, wafers and solar glass — from China between 2021 and 2023, according to a BloombergNEF report at the end of last year.

Senior Biden administration officials said it is not realistic to think that inputs from China can be excluded at this moment from American supply chains. “We have taken a more practical view that in order to effectively diversify, the first step is to get a foothold in the parts of this supply chain where you can diversify today. And then from there you can grow upstream,” said a senior administration official, speaking on the condition of anonymity to discuss sensitive strategies toward China.

Addressing the significant presence of Chinese components in Indian-made solar panels, the official said: “We recognize we are in the first inning of a long game, but we are at an inflection point in that there is now a clear recognition, not just in the U.S. and India but among friends and allies, that being overly reliant on one source for the clean-energy economy is not sustainable and requires a concerted effort to de-risk. But it’s going to take time.”

Sep 2, 2024

Riaz Haq

India's bid to match China's factory heft gets a reality check

https://www.reuters.com/business/indias-bid-match-chinas-factory-he...

India considers easing Chinese investment rules to boost manufacturing

Visa issuance for Chinese nationals has been eased to support local manufacturing

India's trade deficit with China has nearly doubled since 2020

NEW DELHI, Sept 11 (Reuters) - India's push to become a factory titan has hit a snag: to become a credible alternative to China for global firms, it first needs to warm up to its long-time rival.

Ties between the world's two most populous countries have been strained since a deadly Himalayan border clash in 2020, slowing the exchange of capital, technology and talent, despite exploding demand for electric vehicles, semiconductors and artificial intelligence.

The Modi government's heightened vetting of all Chinese investment over this period effectively turned away billions of dollars from the likes of BYD, Great Wall Motor and created new layers of red tape for Indian firms with Chinese stakeholders.

But now, New Delhi is looking to loosen some of these restrictions as businesses struggle to scale up manufacturing, even with a host of government subsidies designed to boost local production.

"There is a realisation that you cannot be part of any major supply chains, especially in high technology products and certain areas like solar cells, EVs, where it is not possible for you to do anything without being part of Chinese supply chains," said Sushant Singh, lecturer at Yale University, who has also been a researcher for public policy think tanks in India.

Even businesses that have supported barriers on Chinese imports acknowledge the need for key inputs from up north.

Naveen Jindal, head of one of the country's largest steel firms Jindal Steel & Power and a federal lawmaker, has backed tariffs on Chinese steel but also sees the need for a pragmatic approach to trade.

"A lot of steel companies import equipment and technology from China," Jindal said. "China is the world's largest producer of steel and in certain areas they are very good, but not in every area."

Now, after four years of restrictions on Chinese investments and visas, Prime Minister Narendra Modi's government is looking to pivot closer to the Asian rival and breathe new life into his ambitions to "Make in India".

Sep 11, 2024