PakAlumni Worldwide: The Global Social Network

The Global Social Network

Is Modi's "Make in India" All Hype?

Some of Prime Minister Narendra Modi's supporters claim that his "Make in India" campaign has brought India to the verge of becoming a manufacturing behemoth 69 years after the nation's independence. Others claim India is already a manufacturing powerhouse. Let's examine these claims based on data.

Manufacturing Ranking:

While India now ranks 6th in the world in terms of total manufacturing output, it still sits at a very low 142nd position terms of manufacturing value added per capita, according to the United Nations Industrial Development Organization's Industrial Development Report 2016. Pakistan's manufacturing value added is ranked 146th by the same report.

Manufacturing Output:

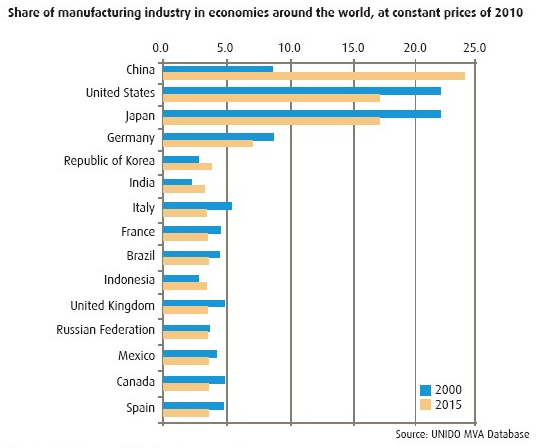

India's 3% share of the world's total manufacturing output puts it at a distant sixth position behind China's 24%, United States' 17%, Japan's 16%, Germany's 7% and South Korea's 4%.

The UNIDO data shows that India's manufacturing value added (MVA) per capita at constant 2005 prices increased from US$155.73 in 2005 to $168.42 in 2014. However, as percentage of GDP at constant 2005 prices in US$, India's MVA decreased from 15.10% in 2005 to 13.85% in 2014

UNIDO reports that Pakistan manufacturing value added (MVA) per capita at constant 2005 prices increased from US$135.03 in 2005 to $143.84 in 2014. Its MVA as percentage of GDP at constant 2005 prices in US$ decreased from 18.05% in 2005 to 17.41% in 2014.

India's manufacturing output declined 0.7% in April-June 2016-17 |

Make in India:

Prime Minister Narendra Modi has recognized how far behind India is in the manufacturing sector. His government's highly publicized "Make in India" is designed to Change that.

What does India, or for that matter any other developing country, need to boost its manufacturing output? Most experts agree on two essential pre-requisites for industrial development:

1. Energy and Infrastructure

2. Skilled Manpower

China's rapid industrialization over the last few decades has shown that the focus must be on the above two to achieve desired results. Has India learned from the Chinese experience? Let's examine this question.

Energy and Infrastructure Development:

"Infrastructure is the biggest hurdle to the ambitious Make in India program of the government," Standard and Poor Global Ratings Credit Analyst Abhishek Dangra told reporters on a conference call, according to India's Economic Times publication.

"The government is scaling up spending, but its heavy debt burden could derail its ambitions to improve public infrastructure," the Standard and Poor report said.

India suffers from huge energy deficit. Over 300 million of India’s 1.25 billion people live without electricity. Another 250 million get only spotty power from India’s aging grid, with availability limited to three or four hours a day, according to an MIT Energy Report. The lack of electricity affects rural and urban areas alike, limiting efforts to advance both living standards and the country’s manufacturing sector.

Skilled Manpower:

“India doesn’t have a labor shortage—it has a skilled labor shortage,” said Tom Captain, global aerospace and defense industry leader at Deloitte Touche Tohmatsu, according to a Wall Street Journal report.

The WSJ report said that over 80% of engineers in India are “unemployable,” according to Aspiring Minds, an Indian employability assessment firm that did a a study of 150,000 engineering students at 650 engineering colleges in the country.

NPR's Julie McCarthy reported recently that ten million Indians enter the workforce every year. But according to the Labour Bureau, eight labor-intensive sectors, including automobiles, created only 135,000 jobs last year, the lowest in seven years.

Impact on Agriculture:

Prime Minister Modi's focus on manufacturing is talking away resources and attention from India's farmers who are killing themselves at a rate of one every 30 minutes.

Majority of Indian farmers depend on rain to grow crops, making them highly vulnerable to changes in weather patterns. As a comparison, the percentage of irrigated agricultural land in Pakistan is twice that India.

More than half of India's labor force is engaged in agriculture. Value added per capita is among the lowest in the world. Pakistan's agriculture value added per capita is about twice India's. This is the main cause of high levels of poverty across India.

Chinese Experience:

China has shown that it is possible to make huge strides in manufacturing while at the same time achieve high productivity levels in agriculture.

On the manufacturing front, China has taken care of the basics like energy, infrastructure and skilled manpower development to achieve phenomenal growth.

As part of the China-Pakistan Economic Corridor (CPEC) development, Pakistanis are learning from the Chinese to replicate success in manufacturing.

The first phases of CPEC are focused on building power plants, gas pipelines, rail lines, roads and ports at a cost of $46 billion. At the same time, China and Pakistan are also focussing on skills training via vocational schools and Pakistan-China Education Corridor. These projects will lay the foundation necessary to ramp up manufacturing in Pakistan.

Summary:

Both India and Pakistan want to emulate the success of China in the manufacturing sector. The Chinese experience has shown that development of energy, infrastructure and skilled labor are essential to achieve their manufacturing ambitions. The South Asians must move beyond hype to do the hard work necessary for it. Pakistan is working with China via CPEC to make progress toward becoming a manufacturing powerhouse.

Related Links:

Auto Industry in India and Pakistan

UN Industrial Development Report 2016

China-Pakistan Economic Corridor

-

Comment by Riaz Haq on August 6, 2023 at 8:00am

-

Fingers ‘turned to powder’: maimed workers of #India’s #automobile hub in #Haryana. Poor training, shoddy equipment leave thousands of auto workers injured. 52% of accidents happen on power press machine, 47% of workers had low-quality safety gear. #MakeInIndia #safety https://www.aljazeera.com/economy/2023/8/4/crushed-fingers-hands-ma...

At the break of dawn, thousands of workers walk out from dusty and congested maze-like alleys to work at nearby factories in Manesar, one of India’s leading automobile hubs, about 50km (31 miles) south of the capital.

In India, the automobile industry employs around 3.7 million people and contributes 7.1 percent to the gross domestic product (GDP). Just in Manesar and the next-door city of Gurugram, both in Haryana state, approximately 80,000 workers are employed in different automobile units of Hero MotoCorp, Maruti Suzuki, Yamaha, and other global companies.

Waiting restlessly outside a government dispensary for his turn, Manish Kumar, 20, a worker at one such factory in Manesar, quickly covers his bandaged hand with a piece of cloth as a group of workers walk past him. In February, Manish lost two fingers when a power press machine, used in the manufacturing of car windows, came crashing down on his hand.

“I came to Manesar like thousands of other workers to support my family and for a better future. But little did I know, instead, this place would make me dependent on someone for the rest of my life,” Manish told Al Jazeera.

“The incident is fresh in my mind and I get traumatised when someone asks me what happened to your hand, and that’s why I try to hide it most of the time,” he said.

Before the outbreak of the COVID-19 pandemic, Manish worked as a casual labour in his central Indian state, Madhya Pradesh. To meet his daily ends and support his ailing parents, he boarded a bus to Manesar, like hundreds of others from his village, in search of a better job opportunity. Soon at the recommendation of a friend, he landed a job that would earn him 13,500 rupees ($163) per month in a small factory manufacturing parts for auto major Maruti Suzuki.

“The factory owners don’t care about our safety; their main agenda is production should not stop at any cost … The machine I was working on malfunctioned for a week, and still I was made to work on it instead of getting it repaired. The machine crushed my two fingers due to their negligence, turning them into powder.”

“It has been over a month, and still, I don’t know whether I will ever be able to work again,” said Manish while struggling to clear drops of sweat dripping from his face. He said he is yet to receive any compensation for his injury.

Like Manish, thousands of others have been injured while working in this sector in India. “Crushed”, a report published by Safe in India Foundation (SII) revealed that, on average, 20 workers lose their hands and/or fingers daily while working in automobile factories spread in the Manesar and Gurgaon areas. Around 65 percent of injured workers are under the age of 30.

The automobile manufacturing sector in India recorded 3,882 incidents of injuries including 1,050 deaths in 2020, according to data from the Directorate General Factory Advice Service and Labour Institutes (DGFASLI). That year, the state of Haryana reported 50-60 nonfatal accidents, it said. However, SII says that figure is far from reality as each year it helps at least 4,000 workers suffering from a range of injuries in the state’s auto sector.

-

Comment by Riaz Haq on August 15, 2023 at 8:31pm

-

Ritesh Kumar Singh

@RiteshEconomist

India's premature #deindustrialisation: 12 out of the 23 #manufacturing industries that make up the IIP (Index of Industrial Production) are at levels lower than 7 years ago

@moneycontrolcom

https://twitter.com/RiteshEconomist/status/1691499535170674698?s=20

-----------------

India's industrial growth falls to 3.7% in June

https://www.moneycontrol.com/europe/?url=https://www.moneycontrol.c....

India's industrial output grew by 3.7 percent in June, according to data released by the Ministry of Statistics and Programme Implementation on August 11.

At 3.7 percent, the latest industrial growth figure as per the Index of Industrial Production (IIP) is at a three-month low. It is also below the consensus estimate of 5 percent.

Industrial growth had come in at 5.2 percent in May - now revised to 5.3 percent - and was 12.6 percent in June 2022.

For the first quarter of 2023-24, IIP growth stood at 4.5 percent, down from 12.9 percent in April-June 2022 when the data was boosted by a favourable base effect.

Industrial growth in June was dragged down by a weaker increase in the manufacturing output, which rose by 3.1 percent year-on-year compared to 5.8 percent in May.

The performance of the manufacturing sector has an outsized impact on the headline industrial growth number as the sector accounts for more than three-fourths of the IIP.

While manufacturing output grew at a slower pace, that of mining and electricity rose at a faster clip. In June, mining output rose by 7.6 percent, up from 6.4 percent in May, and electricity production was up 4.2 percent. In May, electricity production was up a mere 0.9 percent.

The improved performance of mining and electricity sectors was down the low rainfall in June as drier conditions allow increased mining activity.

"IIP growth print in June has disappointed," said Suman Chowdhury, chief economist and head of research at Acuité Ratings & Research.

"Clearly, the manufacturing sector has not been able to sustain the growth trend that had been seen in the first two months of the last quarter. The manufacturing output grew only by 3.1 percent and actually saw a sequential contraction of almost 1 percent," Chowdhury added.

"Within manufacturing, output in metals exhibited a healthy performance while export-intensive categories such as textiles and wearing apparel continued to remain pressured," noted Rajani Sinha, chief economist at CareEdge.

In terms of the use-based classification of goods, there were some big shocks. While production of primary and intermediate good rose at a greater rate in June - 5.2 percent and 4.5 percent, respectively - there were weaknesses in other spheres, with output of consumer durables falling 6.9 percent in June after rising for the for the first time in six months in May.

Capital goods' output was up just 2.2 percent - down from 8.1 percent in May - while that of consumer non-durables rose a mere 1.2 percent. in May, it had posted a growth of 8.4 percent.

Output of infrastructure goods grew by 11.3 percent - the same as in May.

According to Aditi Nayar, ICRA's chief economist, the performance of most high-frequency indicators improved in July relative to June, although there were some laggards in the form of vehicle registrations and finished steel consumption.

"Based on these trends, ICRA expects the IIP growth to witness an uptick to 4-6 percent in July," Nayar said.

-

Comment by Riaz Haq on August 19, 2023 at 4:51pm

-

Ritesh Kumar Singh

@RiteshEconomist

Replacing a supplier from China with one in a friendly country would seem to make a supply chain more resilient to a potential China-US conflict; but it may create a false sense of security, considering that many friendly suppliers still rely on China for key inputs

@Kanthan2030

https://twitter.com/RiteshEconomist/status/1692848048144335220?s=20

------------

https://www.project-syndicate.org/commentary/populist-economic-poli...

Aug 18, 2023

RAGHURAM G. RAJAN

Since the 2008 global financial crisis discredited the old liberal orthodoxy, the door has been open for simplistic policies, in part because most people tend to focus only on a policy’s first-order effects. Unfortunately, everyone will have to learn the hard way why such policies fell out of favor in the first place.

CHICAGO – Even in the best of times, policymakers find it difficult to explain complex issues to the public. But when they have the public’s trust, the ordinary citizen will say, “I know broadly what you are trying to do, so you don’t need to explain every last detail to me.” This was the case in many advanced economies before the global financial crisis, when there was a broad consensus on the direction of economic policy. While the United States placed greater emphasis on deregulation, openness, and expanding trade, the European Union was more concerned with market integration. In general, though, the liberal (in the classical British sense) orthodoxy prevailed.

So pervasive was this consensus that one of my younger colleagues at the International Monetary Fund found it hard to get a good job in academia, despite holding a PhD from MIT’s prestigious economics department, probably because her work showed that trade liberalization had slowed the rate of poverty reduction in rural India. While theoretical papers showing that freer trade could have such adverse effects were acceptable, studies that demonstrated the phenomenon empirically were met with skepticism.

The global financial crisis shattered both the prevailing consensus and the public’s trust. Clearly, the liberal orthodoxy had not worked for everyone in the US. Now-acceptable studies showed that middle-class manufacturing workers exposed to Chinese competition had been hit especially hard. “Obviously,” the accusation went, “the policymaking elites, whose friends and family were in protected service jobs, benefited from cheap imported goods and could not be trusted on trade.” In Europe, the free movement of goods, capital, services, and people within the single market were seen as serving the interests of the EU’s unelected bureaucrats in Brussels more than anyone else.

-

Comment by Riaz Haq on September 1, 2023 at 8:35am

-

India Made It to the Moon. That Doesn’t Make It a Top #Industrial Power. #Chandrayaan3Landing will not move big roadblocks on #India’s path to becoming a top industrial power. #Modi's “Make in India” hasn’t done much. #MakeInIndia #manufacturing #BJP

https://www.barrons.com/articles/india-moon-landing-industrial-powe...

India took a giant leap into the ranks of advanced industrial nations when its Chandrayaan-3 unmanned spacecraft landed near the moon’s south pole on Aug. 23. At least to hear Prime Minister Narendra Modi tell it. “Science and technology are the foundations of a bright future for our nation,” the 72-year-old Modi, who is favored to win a third term next year, told ecstatic staff at the Indian Space Research Organization, or ISRO.

----------

Manufacturing’s share of gross domestic product is stuck at about 18%, according to S&P Global. That compares with 28% for China.

Modi’s (not very realistic) target is 25% by 2025. One big obstacle is policy-related: His government remains keen on import tariffs, some of which hit inputs needed to raise exports. “The Indian government has consistently raised tariff and nontariff barriers to protect domestic suppliers across most sectors,” the United States Trade Representative wrote in a recent report.

Another is a lag in transport infrastructure. Indian ports can’t accommodate the biggest container ships, so freight has to be transshipped through Singapore or Hong Kong. “To become the global manufacturing destination of choice, India will need massive upgrades in rail, port, and freight corridors,” write S&P researchers. That won’t happen by gazing at the moon.

-

Comment by Riaz Haq on September 30, 2023 at 10:29pm

-

Sushant Singh

@SushantSin

Even after PLI subsidy, iPhones assembled in India are 13% more expensive. This makes little sense.

https://x.com/SushantSin/status/1707950330653159901?s=20

--------------

Apple absorbs higher costs on 'Made in India' iPhones despite PLI scheme

Under the PLI scheme, Apple's contract manufacturers get incentives ranging from an average of 4-6 per cent annually

https://www.business-standard.com/companies/news/why-iphones-are-st...

-

Comment by Riaz Haq on September 30, 2023 at 10:29pm

-

Sushant Singh

@SushantSin

Even after PLI subsidy, iPhones assembled in India are 13% more expensive. This makes little sense.

https://x.com/SushantSin/status/1707950330653159901?s=20

--------------

Apple absorbs higher costs on 'Made in India' iPhones despite PLI scheme

Under the PLI scheme, Apple's contract manufacturers get incentives ranging from an average of 4-6 per cent annually

https://www.business-standard.com/companies/news/why-iphones-are-st...

-

Comment by Riaz Haq on September 30, 2023 at 10:29pm

-

Apple CEO Tim Cook: This Is the No. 1 Reason We Make iPhones in China (It's Not What You Think)China is much more than a source of low-cost, low-skilled labor.

https://www.inc.com/glenn-leibowitz/apple-ceo-tim-cook-this-is-numb...

Apple CEO Tim Cook: "I'm not sure what part of China they go to, but the truth is China stopped being the low-labor-cost country many years ago. And that is not the reason to come to China from a supply point of view. The reason is because of the skill, and the quantity of skill in one location and the type of skill it is"

And China has an abundance of skilled labor unseen elsewhere, says Cook:

The products we do require really advanced tooling, and the precision that you have to have, the tooling and working with the materials that we do are state of the art. And the tooling skill is very deep here. In the U.S., you could have a meeting of tooling engineers and I'm not sure we could fill the room. In China, you could fill multiple football fields.

The number one reason why we like to be in China is the people. China has extraordinary skills. And the part that's the most unknown is there's almost two million application developers in China that write apps for the iOS App Store. These are some of the most innovative mobile apps in the world, and the entrepreneurs that run them are some of the most inspiring and entrepreneurial in the world. Those are sold not only here but exported around the world.

Highly skilled software developers developing apps for the App Store are one reason Apple likes to be in China. But the depth of highly skilled labor in the manufacturing space is why Apple makes its iPhones there:

China has moved into very advanced manufacturing, so you find in China the intersection of craftsman kind of skill, and sophisticated robotics and the computer science world. That intersection, which is very rare to find anywhere, that kind of skill, is very important to our business because of the precision and quality level that we like. The thing that most people focus on if they're a foreigner coming to China is the size of the market, and obviously it's the biggest market in the world in so many areas. But for us, the number one attraction is the quality of the people.

Citing an example of the type of a highly skilled supplier Apple works closely with, Cook talked at length about recently visiting one company that it has collaborated with for several years:

I visited ICT--they manufacture, among other things, the AirPods for us. When you think about AirPods as a user, you might think it couldn't be that hard because it's really small. The AirPods have several hundred components in them, and the level of precision embedded into the audio quality--without getting into really nerdy engineering--it's really hard. And it requires a level of skill that's extremely high.

And the idea that Apple simply hands over the design to a company like ICT, which just manufacturers according to spec, is simply untrue, says Cook:

It's not designed and sent over--that sounds like there's no interaction. The truth is, the process engineering and process development associated with our products require innovation in and of itself. Not only the product but the way that it's made, because we want to make things in the scale of hundreds of millions, and we want the quality level of zero defects. That's always what we strive for, and the way that you get there, particularly when you're pushing the envelope in the type of materials that you have, and the precision that your specifications are forcing, requires a kind of hand-in-glove partnership. You don't do it by throwing it over the chasm. It would never work. I can't imagine how that would be.

Addressing the designed-in-California, made-in-low-cost-China impression that many people have--an impression reinforced by the tagline that is printed on every box containing a new iPhone--Cook had this to say:

Comment

- ‹ Previous

- 1

- …

- 5

- 6

- 7

- Next ›

Twitter Feed

Live Traffic Feed

Sponsored Links

South Asia Investor Review

Investor Information Blog

Haq's Musings

Riaz Haq's Current Affairs Blog

Please Bookmark This Page!

Blog Posts

Pakistani Student Enrollment in US Universities Hits All Time High

Pakistani student enrollment in America's institutions of higher learning rose 16% last year, outpacing the record 12% growth in the number of international students hosted by the country. This puts Pakistan among eight sources in the top 20 countries with the largest increases in US enrollment. India saw the biggest increase at 35%, followed by Ghana 32%, Bangladesh and…

ContinuePosted by Riaz Haq on April 1, 2024 at 5:00pm

Agriculture, Caste, Religion and Happiness in South Asia

Pakistan's agriculture sector GDP grew at a rate of 5.2% in the October-December 2023 quarter, according to the government figures. This is a rare bright spot in the overall national economy that showed just 1% growth during the quarter. Strong performance of the farm sector gives the much needed boost for about …

ContinuePosted by Riaz Haq on March 29, 2024 at 8:00pm

© 2024 Created by Riaz Haq.

Powered by

![]()

You need to be a member of PakAlumni Worldwide: The Global Social Network to add comments!

Join PakAlumni Worldwide: The Global Social Network